STRATONICS

Stratonics Thermal Monitoring Technology

In additive manufacturing (AM), the quality, consistency, and mechanical integrity of components are directly linked to the thermal profile during melting and solidification.

Real-time measurement of key process metrics certifies that thermal trajectories of components during fabrication are built to qualified standards. Advanced process monitoring and control are imperative to develop significant efficiencies in AM and improve the performance and consistency of the equipment.

ThermaViz Technology

®

ThermaViz® Technology is a highly integrated multi-vision sensor system that utilizes sophisticated algorithms to monitor and control thermal-based additive manufacturing (AM) processes. At its core is a patented dual-wavelength imaging pyrometer that delivers emissivity-independent thermal measurements with high spatial and temporal resolution.

Our technology offers:

-

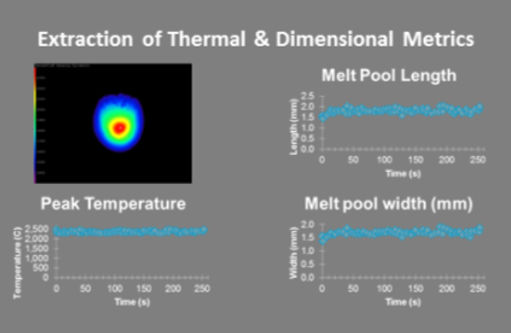

Real-time, high-resolution thermal imaging

-

Real-time sampling of critical thermal metrics

-

Data compression of thermal histories for machine-to-machine consistency

-

Closed-loop feedback for dynamic process control

By continuously comparing real-time data to user-defined setpoints, ThermaViz® adjusts process parameters on the fly—ensuring thermal trajectories stay within qualified limits. Thermal-based monitoring captures key physical aspects of the process; enabling intelligent process control to boost efficiency, improving repeatability, and certify builds to the highest standards.